Mechanical Contractor

ESTABLISHED 1972

Motion Millwright Repairers & Installers

Fabricators & Detailers

Serving performance driven industries

with reliable trustworthy service

You know where we are when you see this.

Insured to work at manufacturing, processing facilities and mines

text message 210.669.6552 ~ 830.560.2109

Email office@millwrightsites.com

meeting maintenance and constructions demands of

concrete - steel - machinery

engineering - maintenance

This company was established in the year 1972 and has been performance driven by the nature of the manufacturing and processing industries that we wanted to serve.

Our ability to identify and solve problems with Engineering followed with a wide range of service sets us apart from other contractors.

Most of our Engineering and service challenges originated from a Customer’s request for maintenance service or a need to rectify a persistent problem at their facility.

And some of our biggest projects were a result of responding to an unplanned outage.

The engineering, concrete, steel and motion millwright skill sets do complement each other and the bundling together of the skills is an absolute necessity for a Competent General Contractor of capital and maintenance projects.

The photographs in this presentation are recent records of our work activities and we will offer you references that will verify what you see in this presentation are fact.

What is a Millwright?

A millwright is a high-precision craftsman or tradesman who installs, dismantles, repairs, reassembles, and moves machinery in factories, power plants, and construction sites.

As the name suggests, the original function of a millwright was the construction of flour mills, sawmills, paper mills and fulling mills powered by water or wind, mostly of wood with a limited number of metal parts. Since both of these structures originated from antiquity, millwrighting could be considered, arguably, as one of the oldest engineering trades and the forerunner of the modern mechanical engineer.

Popular Service disciplines we delivered

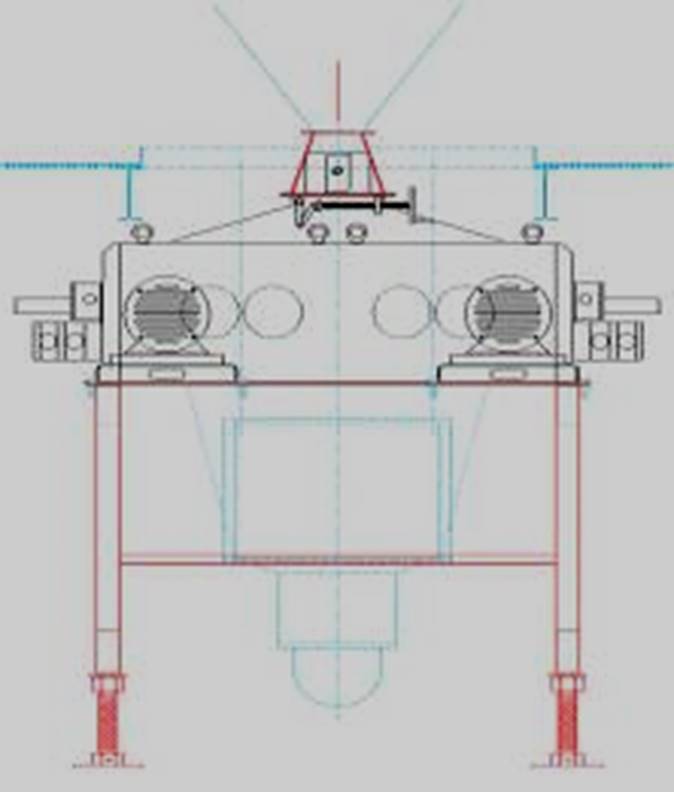

>Crane Systems – design build - testing - modifications

>Water Blasting – cleaning and concrete demolition

>Equipment – installations - retro fits and up grades

>Maintenances – fixes – repairs and replacement’s

>Rail Road Trac receive and load out systems

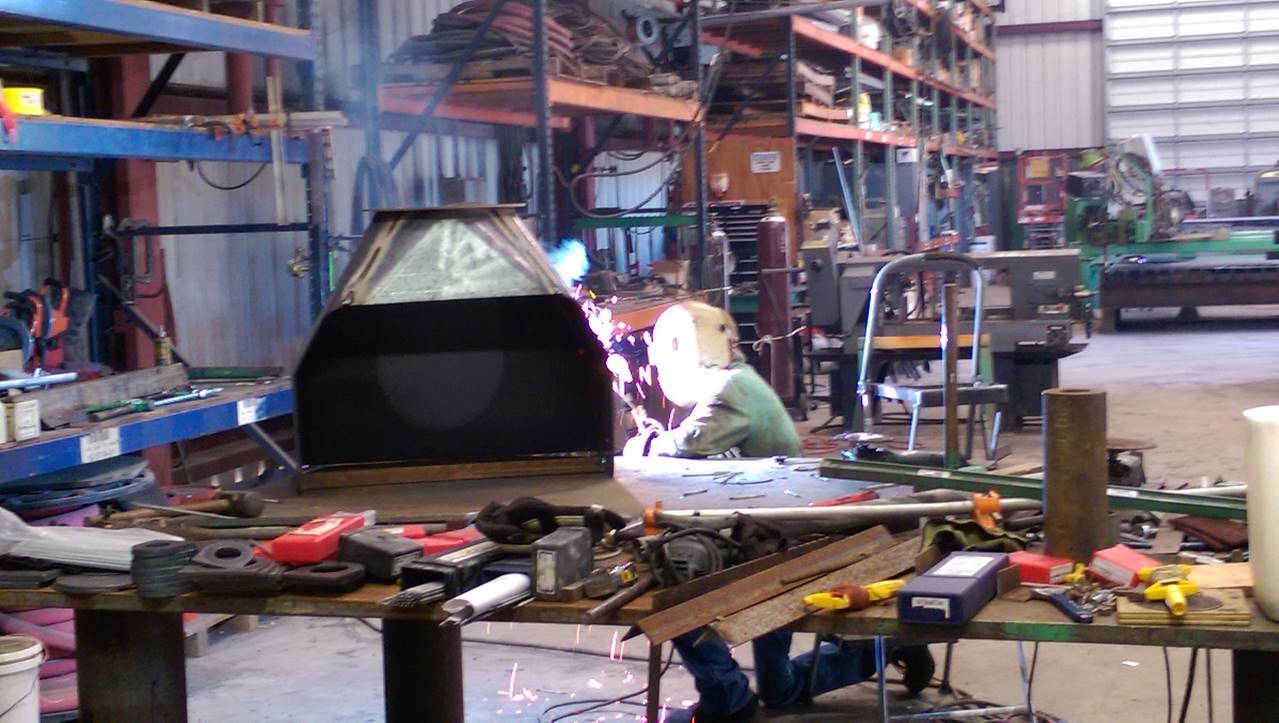

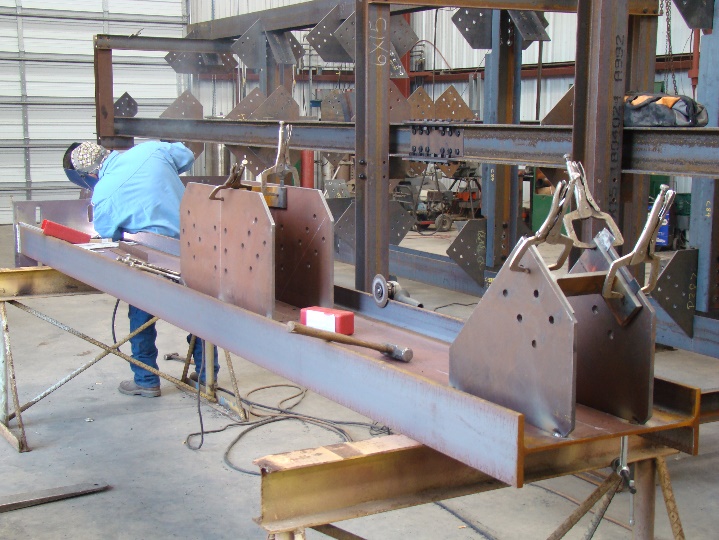

>Steel Fabrication – on site and in fab shop

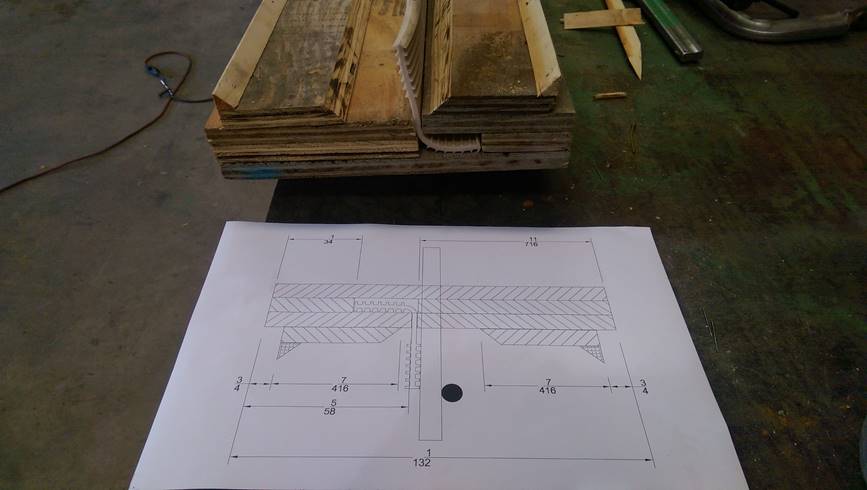

>Engineering - detailing fabrications

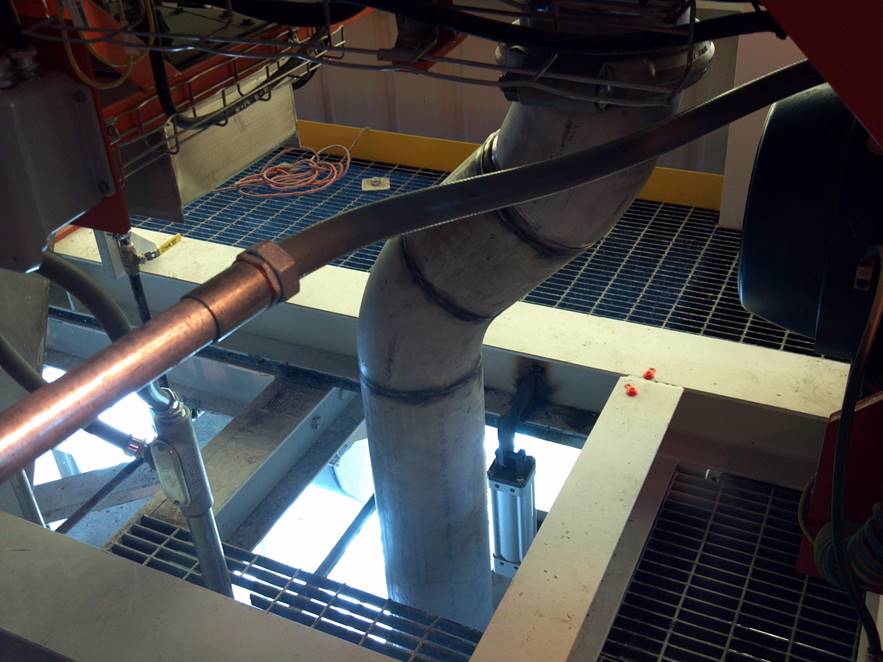

>Piping – above and below ground

>Special buildings and structures

>Concrete – new work – repairs

>Demolition and dismantling

>Environmental projects

>Earth work

Quotations

We will offer multi-staged proposals for projects that are funded and definitely scheduled to proceed.

Additionally we offer to take on functions such as design and management because the procurement routes have become more complex and prospective clients generally want a wide range of goods and services.

Project Management

Delivering the basic benefits of a project management study:

>Using photogrammetry and drones to collect data

>Determine the scopes of work and a schedule of costing

>Finding the lowest cost alternatives using value engineering

>Gantt Chart times and events for the efficiency of the action plan

>Identifying and solving problems with engineering:

*sequence of operations and automation IO’s,

*routings of pipes, conveyers, wheel & foot traffic

*space requirements of operations and maintenance

*power requirements, ventilation, lighting, fire control

*structural frames, equipment arrangements, foundations & etc.

ICC candidate #ICNON040409 MSHA registered contractor

]

]

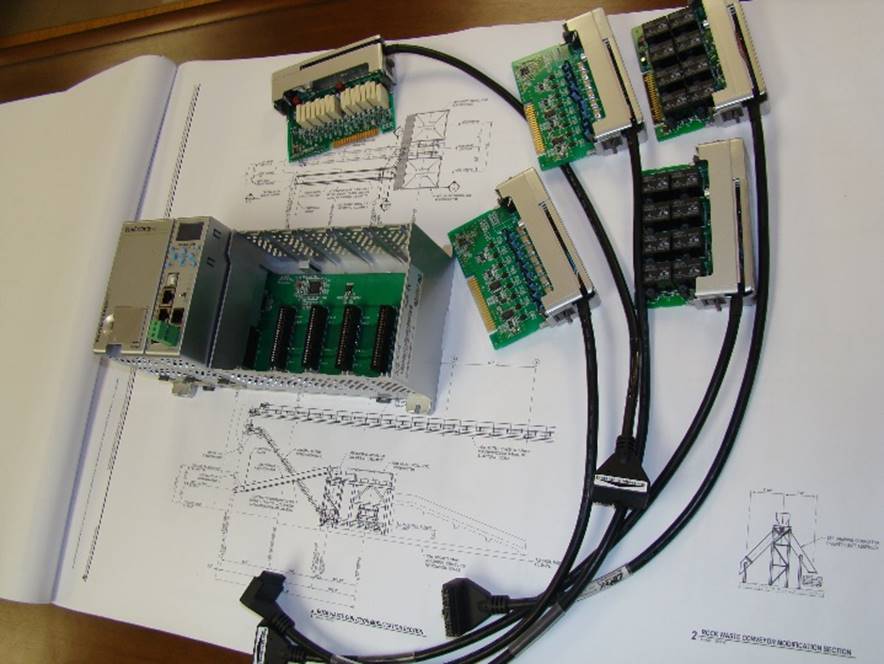

Placement of electrical testing equipment

Installation of a pedestal crane – We built the foundation that supports it

Replacement of electrical transformers in a manufacturing test facility in a town where tacos, barbecue, tequila, and beer are the four basic food groups.

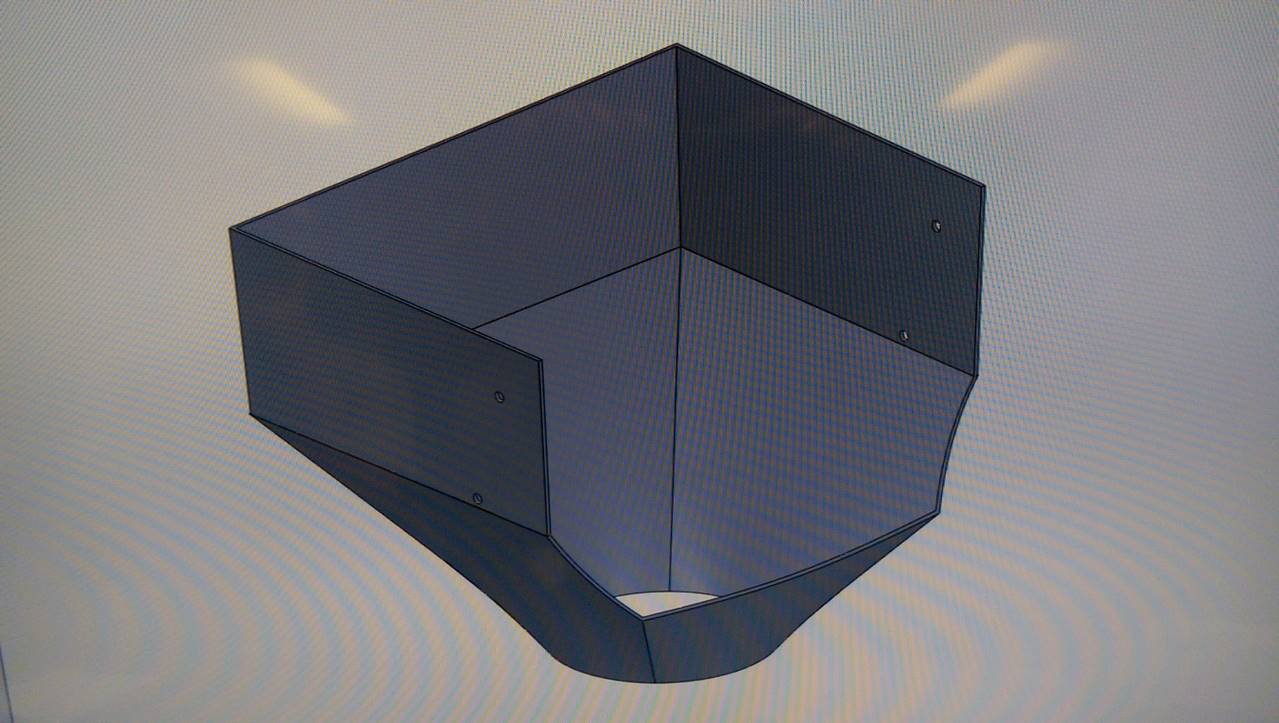

A design-build ventilation project of a cement finish mill building where the wind geratorators out number the legal citizens.

Top row of louvers are 105ft above ground level of which is about 1/2 the height of a wind generator shaft.

A design-build 12ft depth basement foundation

A bulk liquid oxygen storage facility in central Texas where every third or fourth person you meet is an engineer of some sort.

A retro-fit upgrade of a hydraulic mold puller from a spin cast carbon cloth pipe in our fabrication shop

Oxyethermic torch manifold station for steel scrap preparartion

Hot gas bypass duct work at cement mill in South Texas where you know it is a formal occasion when you get a glass with a longneck beer.

Stainless steel chemical piping fabricated in our fabrication shop

line-up of ducting for square fit up of pipe spool

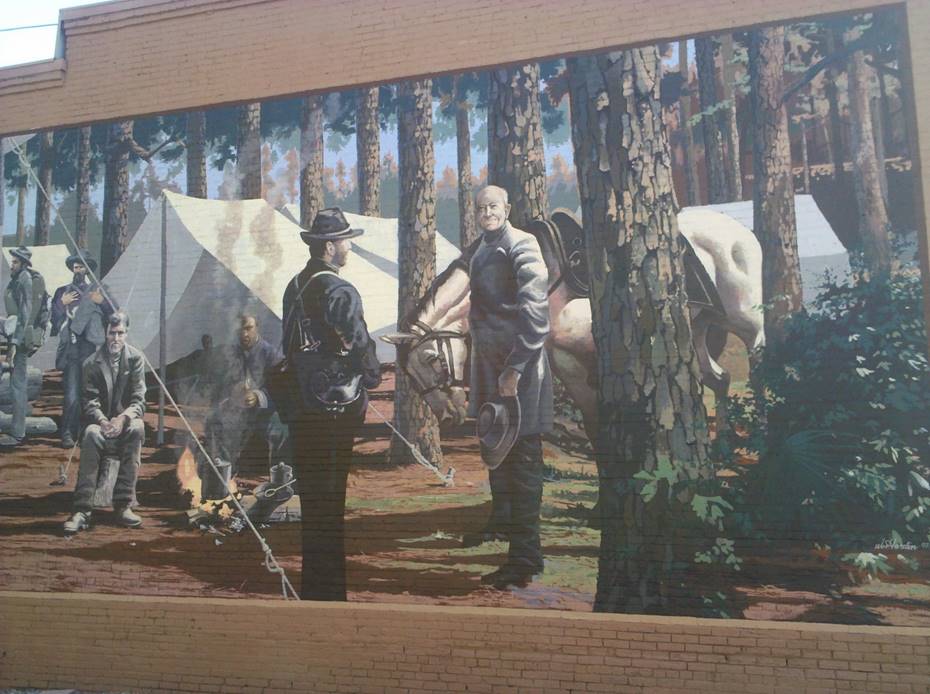

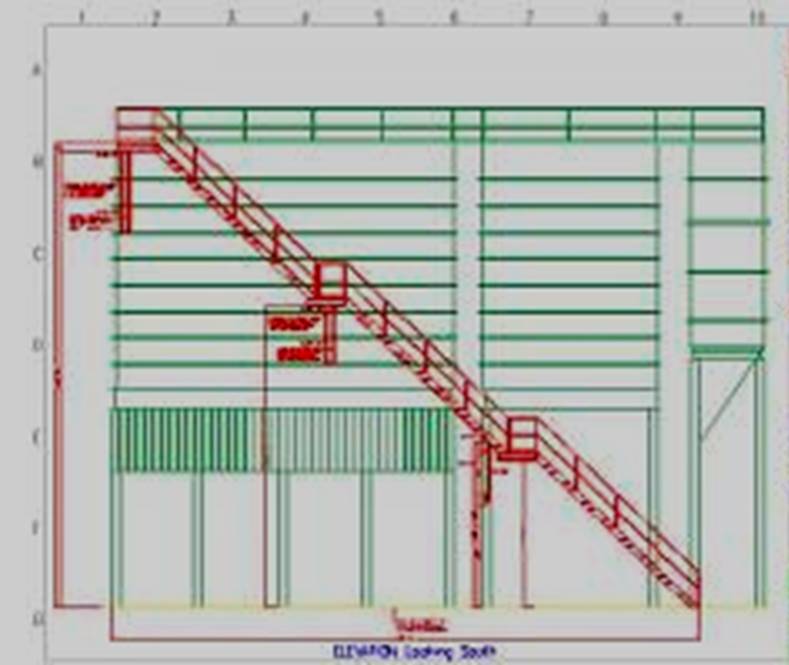

A design-build on the fly of a bulk storage facility, structures, piping, pneumatic conveyor systems, belt conveyors, chutes, spouts, multiple retro-fits of existing process equipment, and the installation of new additional process equipment in a process plant in the great state of Alabama where the legal drinking age is 21, but the “real” drinking age is 14.

We identified and solved problems daily and produce engineered drawings on site just-in -time for schedule outages.

Auger cast foundation piles

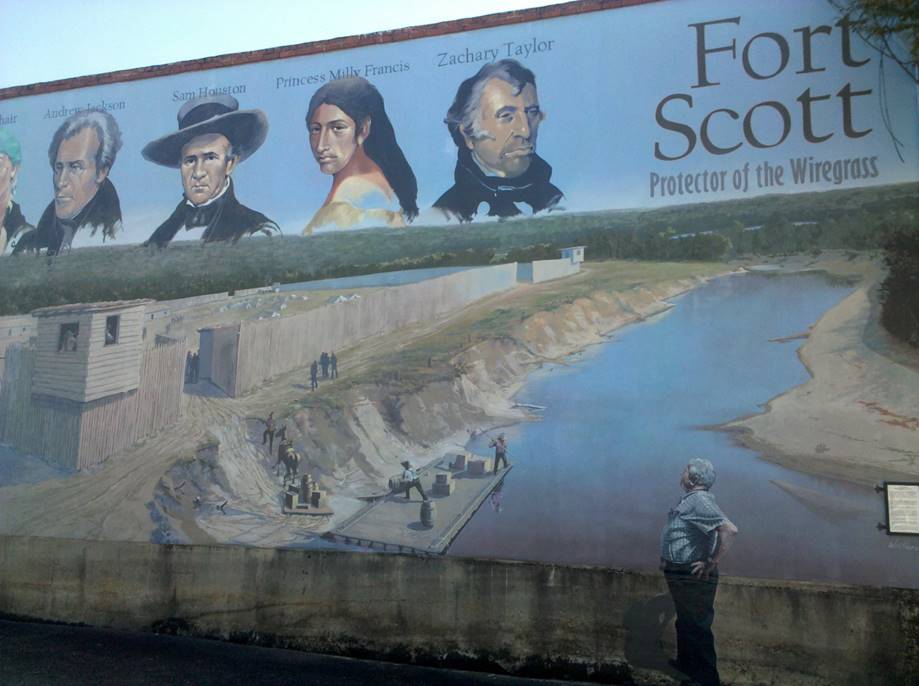

You know that you are in the great state of Alabama when see murals of Sam Houston

Load testing auger cast piles

Testing load capacity of an auger cast pile

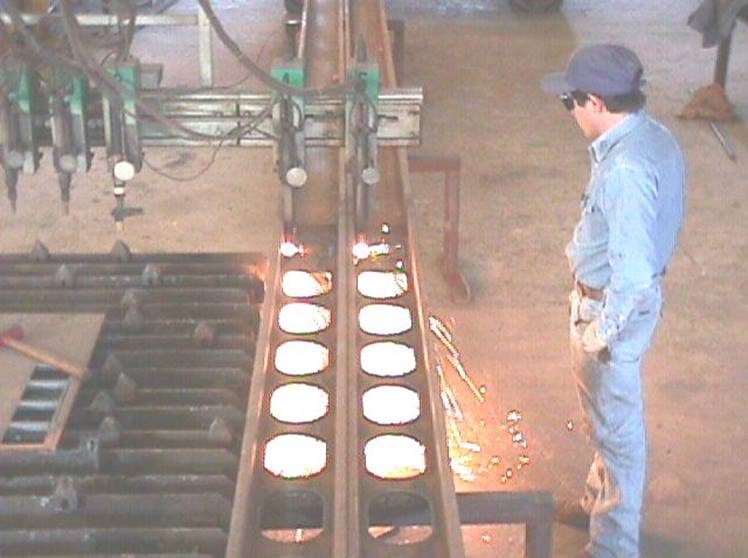

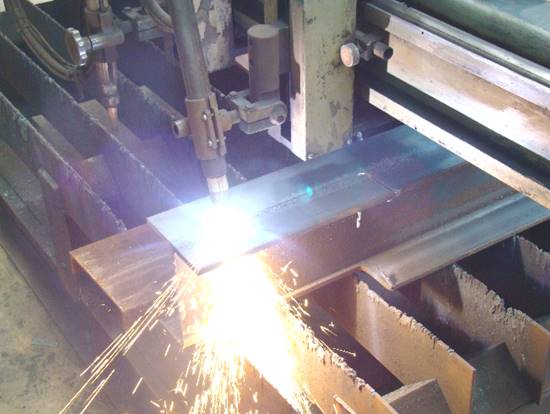

CNC shape cutting on job site

A cut-in door to the elevated production floor for crane service landing.

Cutting pipe to length

A design-build roof opening for crane access of centrafuge machines on the elevated production floor

We modified the roof structure to make this possilble.

You know where you are when you ask a cattleman “how is business?” and he answers the question with one

word “chickenization”.

when Fire Ants

An innovative combination of services

Equipment – installations, retro fits, & up grades

Steel Fabrication – on site & fabrication shop

Maintenance – fixes, repairs, & replacements

Shot Crete – ponds, tanks, walls, & refractory

Water blasting – cleaning & demolition

Special buildings & structures

Concrete – repairs & new work

Piping above & below ground

Demolition & dismantling

Environmental projects

A quick and easy process

Our proposal has some clear advantages

You will be informed of the specifics of the scopes of work, a schedule of values, a schedule of events, and a plan.

Send your request for a proposal to:

Motion Millwright service

We raise and lower scale receive decks with hydraulic power and protect our men with cross-beams to replace motion parts under the scale deck.

Text message 210.669.6552 ~ 830.560.2109 ~ or Email office@millwrightsites.com

Elevators – Conveyors – mixers – crushers – pumps - Cranes

spout piping & chutes – Motors – Cyclone Fans

Precise shaft coupling and laser alignments

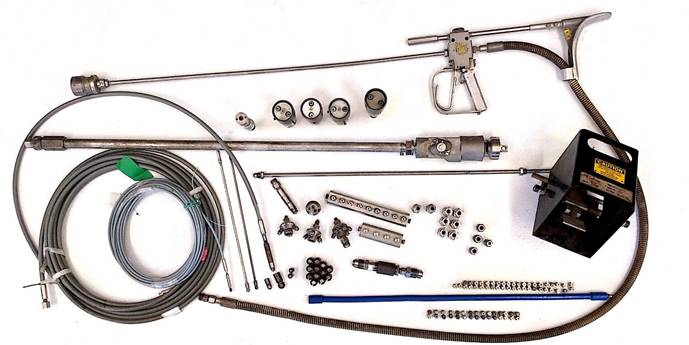

Some of the instruments and tools we use to align shafts and C4 Roller Bearing replacement

We install and repair process equipment

We offer Crew Service for

Maintenance - Construction

text message 210.669.6552 ~ 830.560.2109

Email office@millwrightsites.com

ü Motion Millwright

ü Concrete construction

ü Demolition and dismantling

ü Drilling and cutting concrete

ü Foundation and concrete repairs

ü Piping above and below ground level

ü Metal buildings and special structures

ü Custom steel fabrications on site and fabrication shop

ü Machine repairs and fixes to get the system operational

ü Assembly of equipment and machines thru motion testing

ü Custom shape cutting of steel and stainless-steel plate

ü Precision shaft alignments of motors and transmissions

ü Water blasting for cleaning, flushing pipes and demolition

![]()

a valuable and distinctive service

Engineering - Design-build

Gathering of information to identify and solve problems

immediately followed by fabrication and installation

If you have any experience with getting things done you know that

“Planning before the job is worth more than experience after the job”

Do it right the first time

Engineering is essential to success

Solving details before fabrication begins

Water Blasting

Clearing obstructions in pipes, tubes and silos with water jetting

text message 210.669.6552 ~ 830.560.2109

Email office@millwrightsites.com

Radius concrete fillet keyway cut into a drain tunnel 90ft below ground surface where the city’s homeless reside on a river walk 3 blocks from the state capitol.

Clean and roughen concrete surface preparation for repair compounds

Paint and concrete repair compounds will bond to clean surfaces

Clearing obstructions in pipes, tubes and silos with water jetting

Water blast tools

Lance jetting of condenser tubes

Water Blasting is an exact science requiring the tools for the job. It is not about the pump by itself.

We can automate manual process systems

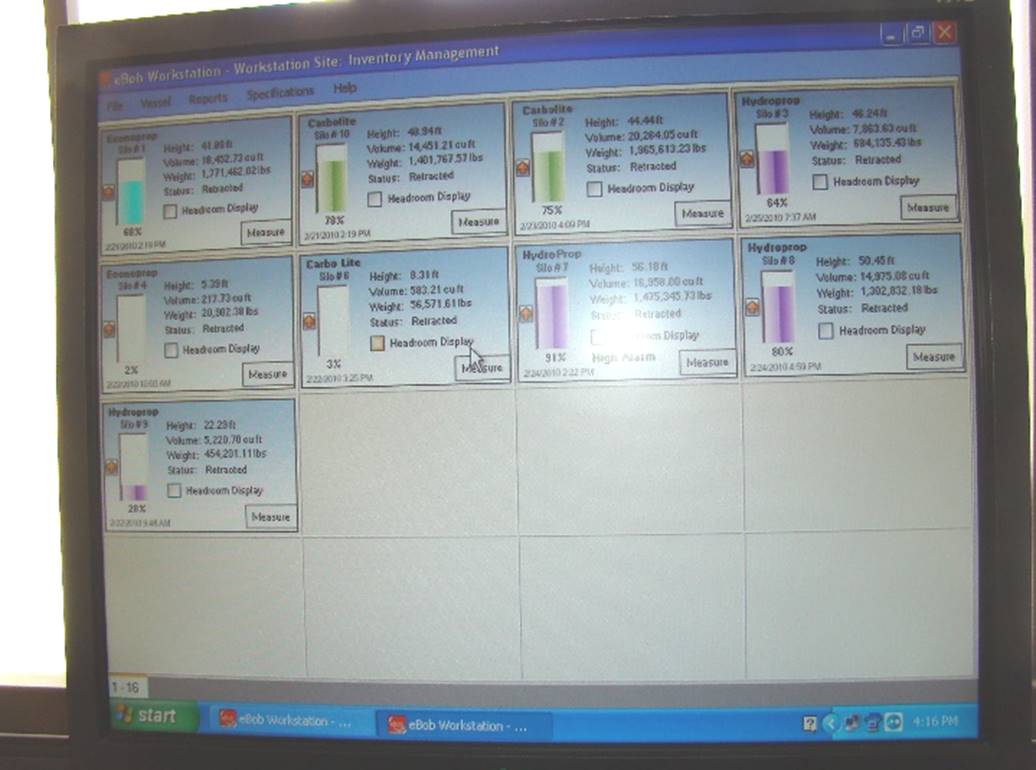

We install Remote Inventory management devices and CPU’s

We install Programmable Automated Controllers

PAC’s are the inexpensive solution for automation

PAC’s are the current generation of PLC’s built on the simple building blocks of step ladder logic and the benefits of a computer, networking and software that is easily learned by anyone with computer experience.

We design-build bulk storage tanks, bucket elevators and towers

A design-build bulk storage facility built in the great state of Louisiana where you can walk down the street with your beer.

Deep foundations built through drilling fluid into t he Mississippi River Basin

Installation of bucket elevator

A design-build Bulk fat storage addition in the best part of Texas, the Brazos Valley.

We CNC Shape cut plates on the job site and at our fab shop

Flanges and connecting plates cut exact

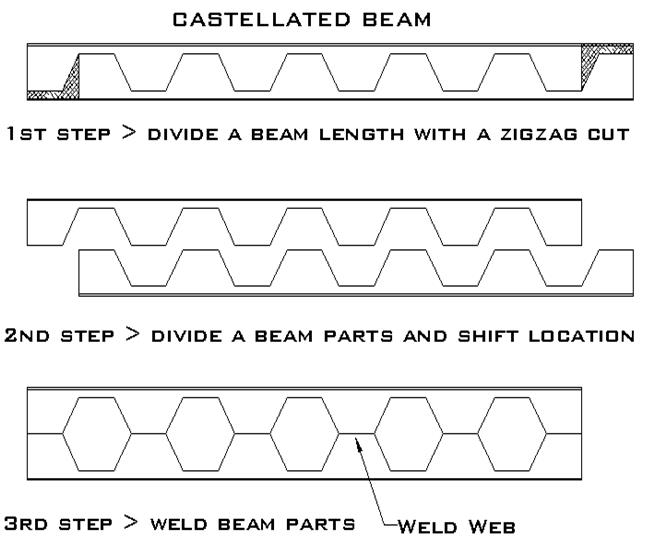

We have castellated beams for many purposes

To lighten structures

To strengthen structures

For mechanical and architectural purposes

We build specific-use buildings

We can provide the rigid Main Frames required

We build portable buildings for offices or living

Up to 22’x 50’ - all steel construction - concrete or wood floor

Fabrication in our fab shop and on the job

A design-build vertical mixer for a feed mill

A design-build 50’ door-crane way truss for jet engine fan plant FY2014

Concrete Construction

We have built bridges

We have built and modified treatment basins

We have placed 1200 cubic yards of concrete in a day

We know the high-performance concretes and grouts

We use reliable prefabricated forming methods

We provide concrete embeds with proven Nelson Studs

drilled pier foundations

We install piping, vaults & tanks of all types

Primary electric power ducts

We cut and drill concrete with diamond tools

Paving removed and replaced in 96 hours

We solve project problems with engineering

We used Engineering modeling procedures to develop a Shot Crete that will bond to old concrete to provide a time driven and durable concrete repair application.

We provide shotcrete wet application for lining tanks and walls, slopes, compression ring shoring, heavy structural repairs.

The Shot Crete application method has been utilized for more than 95 years with some outstanding achievements in tunnels.

the American Concrete Institute committee 506 was organized in 1942 to cover shot Crete standards for the USA. Shot Crete is a proven method used to repair concrete, to build tanks, to seal tunnels and aqua ducts, to shore deep vertical excavations, for domed roofs and to build difficult shaped structures. Shot Crete walls combined with earth screw anchors build superior retaining walls.

>>> Problems solved with Shot Crete are limited by imagination <<<

Remote access and confined space work

We seal leaks from inside tanks

We will accomplish tasks that require remote access

Work solutions for remote access work are practical skills using professional equipment for the job.

Acessing the inaccessable

Replacement of 16” spout pipe 32’ above the mill roof and 177 feet above ground level while mill is running.

Gallery of projects done

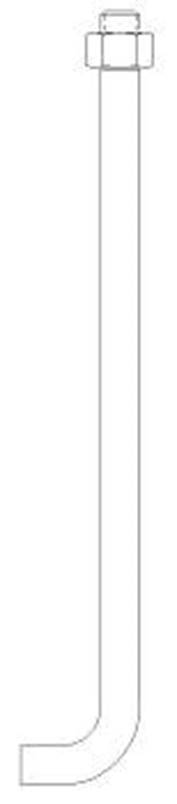

The largest anchor bolt that we have cast into a concrete foundation were

5-inch diameter by 192-inch depth for a 25,000-horsepower synchronous motor

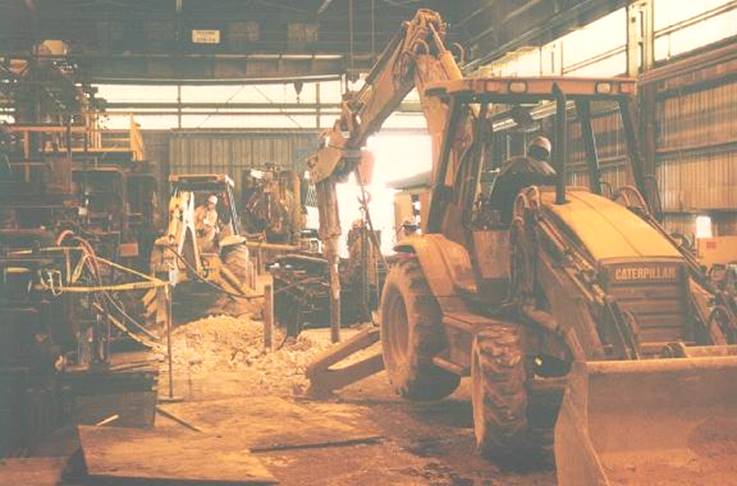

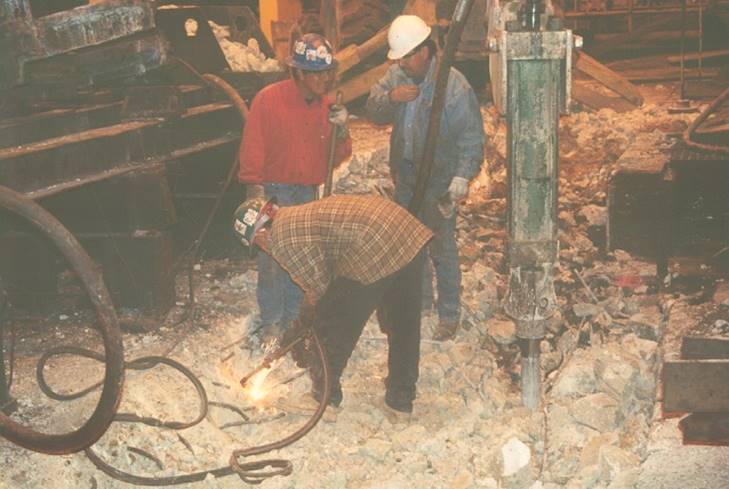

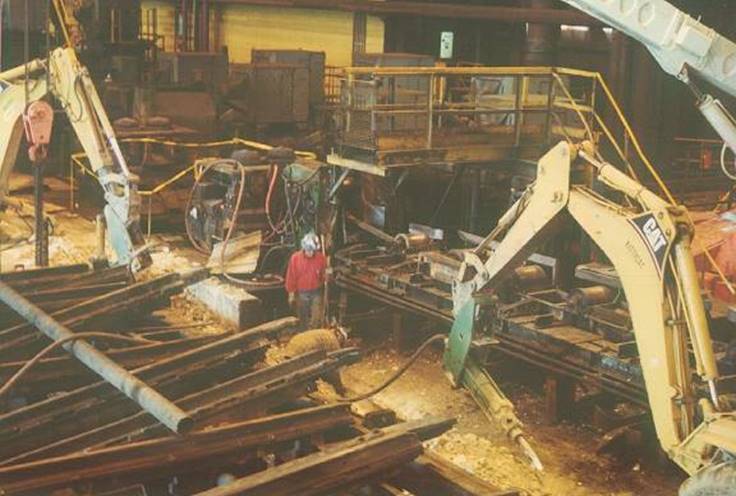

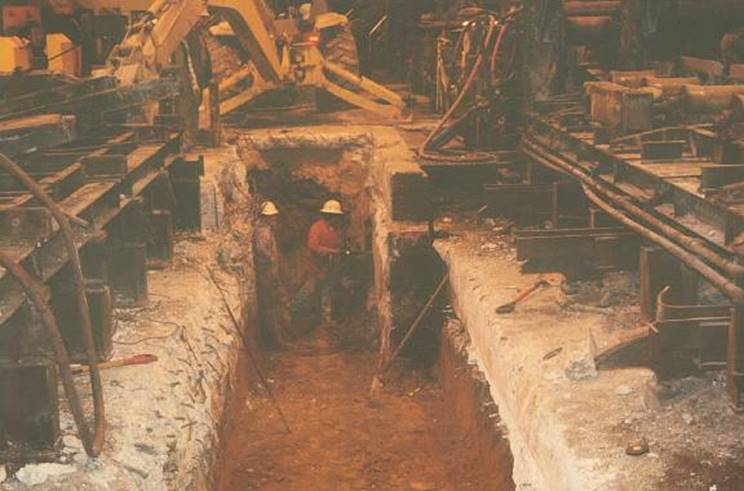

9 ft. depth drain flume cut into floor to a tunnel for a steel mill

Huricane damage repaired where you know where you are when the first things to be used up after a storm is the hot dogs and beer.

We service crane ways and design-build special building additions and shelters

We service transload facilities

W

A design-build truss in an aerospace plant installed to allow installation of a 3rd autoclave.

Emergency response to storm damage Thursday June 12th 2014

The 140 ft. X 55 ft. wall was restored upright and secured 115 hours after the storm

and production was resumed Monday June 15th

Replacing an interference fit bearing with a hyraulic puller

A design-build belt conveyor drop-point diverter with a dust controller